Accutech Machining Inc. "A Commitment to Raising the Bar"

We specialize in delivering high-accuracy machining solutions for industries that demand precision. Our commitment to accuracy, quality, and reliability set us apart. We craft complex parts with unmatched attention to detail.

Our innovative approach and state-of-the-art technology ensure that we meet the evolving needs of our clients.

Our experienced team works closely with clients to provide tailored solutions that enhance productivity and efficiency.

Tailored CNC Machining Services

AccuTech Machining, Inc. provides a full suite of CNC machining services for any manufacturing challenge. Explore our offerings below:

CNC Milling

From complex 3D shapes to intricate details, our multi-axis CNC milling services deliver exceptional precision for even the most demanding designs.

Horizontal Machining Centers:

TOYODA FA-400 400 MM Pallets

TOYODA FA-450 450 MM Pallets

MORI SEIKI NH-4000 400 MM Pallets

Vertical Machining Centers:

MORI SEIKI SV-400 24" x 16" x 20",

MORI SEIKI DURA VERTICAL 5080 35" x 20" x 22",

BROTHER TC-S2C-O

CNC Turning

AccuTech can machine parts to tight tolerances and increase throughput utilizing our (twin spindle, twin turret, and Y-axis) machines that are equipped with LNS Barfeeders. We can barfeed up to 70MM or 2.750" diameter.

TURNING CENTERS:

MORI SEIKI SL-154Y 3 Axis Lathe Equipped with LNS Barfeeder Live Tooling.

EUROTECH E-42,

MORI SEIKI SL-200 2 Axis lathe Equipped with LNS Barfeeder,

MORI SEIKI ZL-25 4 Axis Lathe,

MORI SEIKI NL-2500SY 5 axis lathe with Sub Spindle and live tools,

MORI SEIKI NL-2000SY 5 axis lathe with Sub Spindle and live tools equipped with LNS Barfeeder.

MORI SEIKI NZ1500 T2Y2 8 Axis Lathe with Sub Spindle and live tooling 2 Turrets LNS Barfeeder

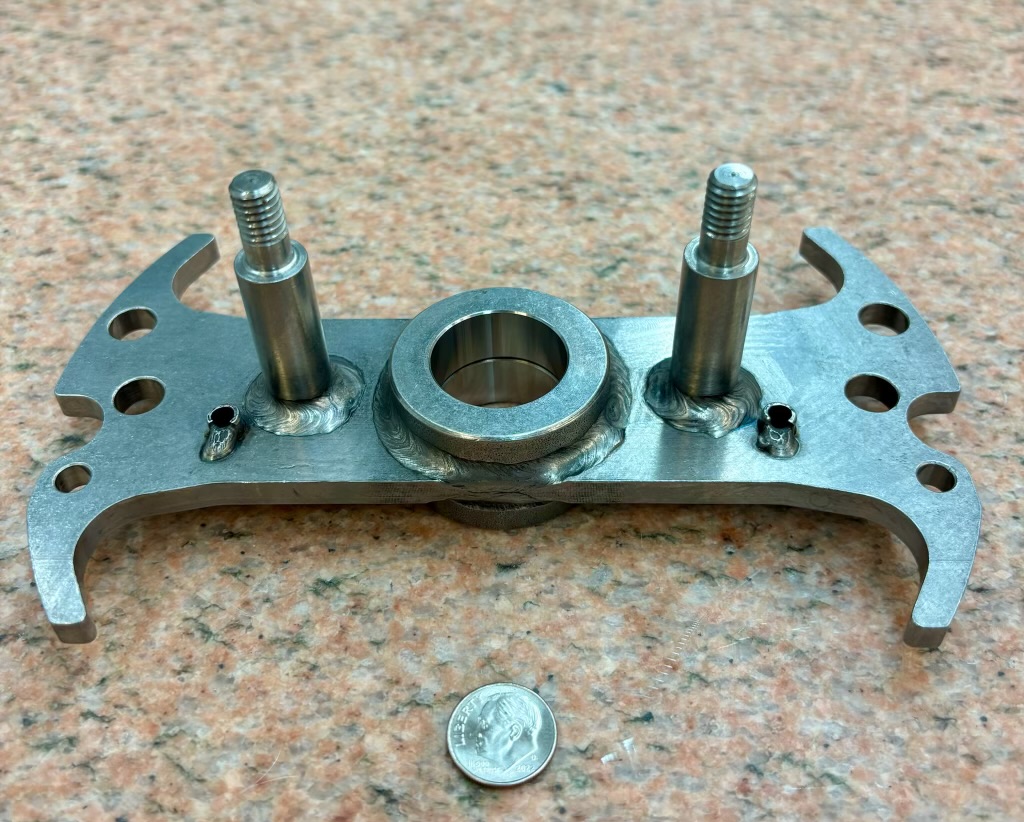

WELDING

AccuTech offers TIG Welding. Capable of welding aluminum and steel.

MILLER TIG WELDER

INSPECTON

We are excited to offer a range of high-precision measurement equipment, including the ZEISS CONTURA G2 CMM and an optical comparator, to meet your quality assurance needs. We are able to provide PPAP, Full ISR (Initial Sample Run) on all dimensions on print. Material Certifications for material, plating and all other outside services.

ZEISS CONTURA G2 CMM, OPTICAL COMPARATOR, MISCELLANEOUS GAGES, TRIMOS HEIGHT GAGE

Why Choose PrecisionMakers CNC?

Experience unparalleled craftsmanship and precision in machining solutions, tailored for industries that require meticulous attention to detail from inception to final product.

Fast Turnaround

With a streamlined workflow utilizing DBA Manufacturing ERP software, we are able to deliver quality parts without compromising lead times, helping you meet tight deadlines.

Custom Solutions

No two projects are the same. Whether you're prototyping or in full production, we tailor our services to meet your unique needs.

About AccuTech Machining, Inc.

AccuTech Machining, Inc. is a family owned precision machining and assembly business specialized in multi-axis turning and milling. Jeff Szwaya is the third generation of shop owners in his family. He began his machining career working for his grandfather and then father before founding AccuTech in 1999. In 2004, AccuTech expanded into its current facility in Bensenville, IL. In conjunction with the expansion into the new facility, AccuTech began investing in multi-axis machining equipment opening the door to better Accuracy and throughput through the use of cutting edge Technology.

Jeff Szwaya brings to the table 35 years of invaluable knowledge of part processing, program development, and manufacturing know how. Industries served but not limited to are: hydraulic, aerospace, automotive, electrical distribution, water technology, veterinary equipment, and medical devices. Whether it’s a small custom order or a large production run, we bring unmatched expertise and innovation to every project.

AccuTech Machining, Inc. is committed to delivering high-quality machining solutions that meet the evolving needs of our clients. AccuTech Machining, Inc. continuously strives to enhance its capabilities and service offerings to ensure customer satisfaction and industry leadership.

Frequently Asked Questions

Some things that our customers usually want to know.

What materials can you work with?

At AccuTech Machining, Inc. we work with a wide range of materials, including but not limited to (aluminum, steel, titanium, brass, all types of stainless steel, Duplex stainless, copper, cast iron), and plastics (ABS, acrylic, nylon). If you have a specific material in mind, feel free to contact us for details.

What’s the maximum part size you can machine?

Our CNC machines can handle a variety of part sizes, from small intricate components to large parts. The maximum size for milling is 35" x 20" x 25", while for turning, we can accommodate diameters up to 12". If your project requires custom dimensions, we’re happy to discuss your needs.

Do you offer prototyping services?

Yes, we do offer prototyping services to help bring your ideas to life with precision and efficiency. Yes, we offer rapid prototyping services to help bring your concept to life.

What quality control measures do you have in place?

Quality is at the heart of everything we do. Every part goes through a stringent inspection process, including Coordinate Measuring Machine (CMM) checks and our Quality Managment System to ensure it meets your exact specifications.

Request an Estimate

Tell us about your project! We typically provide quotes within 1-3 business days after receiving your design files and project details. Our team will review the requirements and get back to you promptly with a detailed cost breakdown. You can also call us at 630-350-2066

Gallery

AccuTech Machining, Inc.

AccuTech Machining, Inc. offers a comprehensive range of machining services, including turning, vertical and horizontal milling, as well as secondary deburring, sanding, and grinding.